Introduction:

Installing a turbocharger requires precision and attention to detail to ensure optimal performance and longevity. One critical aspect of the installation process is pre-lubricating the turbocharger. In this guide, we will emphasize the significance of turbocharger pre-lubrication and provide a step-by-step procedure for successful installation. Let's explore the essential steps below.

Step 1: Ensure Clear Oil Drain Line:

Before starting the installation process, confirm that the oil drain line is securely installed with the provided gasket and free from any obstructions. Clearing the drain line allows for efficient oil flow and prevents potential damage.

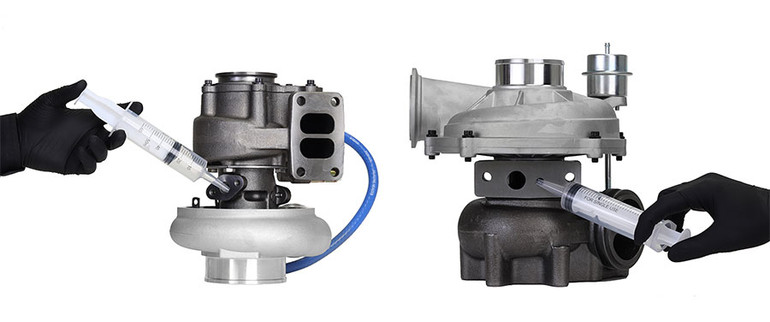

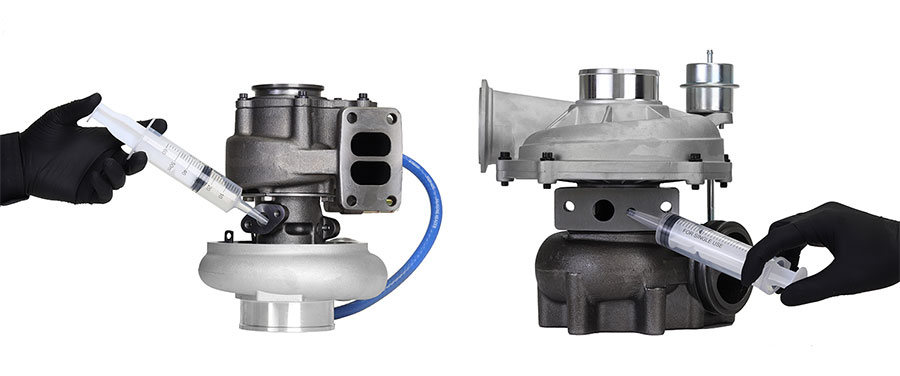

Step 2: Proper Pre-lubrication:

To protect the turbocharger from damage during engine startup, it is crucial to pre-lubricate the unit. Follow these steps:

a. Use clean, recommended engine oil: Prior to engine startup, lubricate the replacement unit with the correct grade of clean engine oil. Refer to the OEM manufacturer's guidelines for the specific oil grade suitable for your vehicle.

b. Utilize the supplied syringe: The special syringe provided with each Rotomaster unit should be used to inject 2 to 3 ounces (50 to 60 cc) of oil into the supply fitting. Carefully rotate the turbine wheel by hand during the injection process. Avoid using compressed air or air tools to prevent potential damage.

Step 3: Oil and Filter Change:

Before starting the engine, ensure that the engine oil and filter(s) are replaced. It is essential to use the oil grade approved by the OEM manufacturer for your particular vehicle/application. Some units feature a micro screen filter inside the oil supply fitting that should be inspected for contamination. Service or replace the screen if necessary.

Step 4: Flush the Oil Supply Line:

To guarantee unrestricted oil flow, it is recommended to flush the oil supply line with clean engine oil. If your application has a rigid oil supply line, consider using a new line to avoid dislodging any caked-on engine oil, debris, or contamination. Flushing the line properly prevents premature failure of the turbocharger.

Step 5: Referring to Installation

For a complete and successful installation, consult the supplied installation instructions and the vehicle service manual. These resources provide specific guidelines tailored to your vehicle model and turbocharger type.

Conclusion:

Proper turbocharger installation is crucial for optimal performance and longevity. Pre-lubricating the turbocharger before engine startup is a critical step to prevent damage and ensure its smooth operation. By following the step-by-step procedure outlined in this guide, including checking the oil drain line, pre-lubricating with clean engine oil, changing the oil and filter, flushing the oil supply line, and referring to the installation instructions, you can ensure a successful turbocharger installation that maximizes performance and extends its service life.